We offer a complex set of component tests. We focus on static and dynamic testing of individual parts or assemblies of aircrafts using computer simulations and destructive testing.

It is possible to conduct various computer simulations which means saving a large amount of money and time compared to more traditional methods. It is also possible to test individual parts and assemblies and find out their mechanical properties and characteristics.

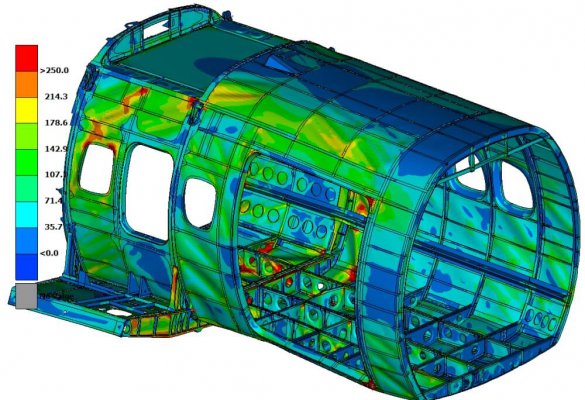

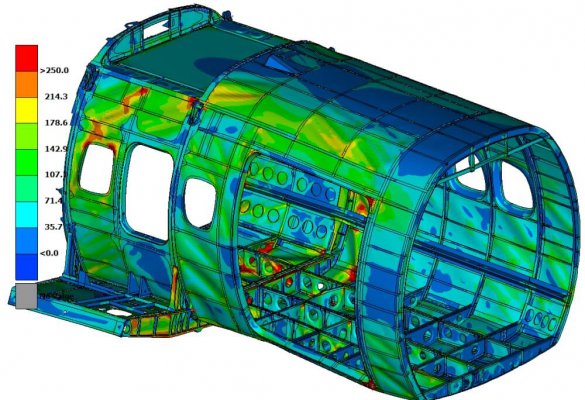

We conduct stress, fatigue, and dynamic analyses using the finite element method and traditional computing methods.

We can also simulate the airflow around the aircraft and determine forces that act on the aircraft or the air velocity around it.

We are able to conduct destructive tests of various components of an aircraft. It is possible to gather data about the mechanical properties of the material this way, for instance, the yield strength or the ultimate tensile strength. Finding out the crucial information regarding the rigidity of individual components and assemblies, their safety, and the high cycle fatigue is possible.

These tests include, among other things, testing the strength of the wing after exceeding the strength limit and testing the components beyond the load limit.

We offer complex services in the area of non-destructive testing of metal and composite materials and designs for all areas of the engineering industry but mainly for the aerospace sector. Surface discontinuity detection, joint checking (riveted, threaded), conductivity measuring, conductive and non-conductive coating testing, analysis of the thermal damage on aluminum constructions, and testing of composite materials are among the used non-destructive testing methods. These analyses are done using visual methods, the eddy current method, ultrasound, and acoustic method, thermo-graphically, etc.

Observation of various operational phenomena that can occur during the service of the components. Usually, these phenomena include vibration, shaking, and acoustic noise. Specialized tools are required to measure and analyze these (for example vibration tables or rockers).

Other possible phenomena include the combination of various types of environments such as temperature, pressure, humidity, cosmic surroundings, or the effects of abrasives.

R&D

Member companies are engaged in research and development of both the construction of the aircraft, its parts, and the technologies used in production.

Production

As one of only a few countries, we're able to manufacture every component completely "in-house".

Testing

We are able to provide a wide range of testing processes. We perform static and dynamic testing.

Special technologies

Our members develop, manufacture, and provide services in the area of special technologies used in the aviation industry.